12 Feb 2019

HILIC method optimisation using combined mobile phases

Much attention has been paid to hydrophilic interaction liquid chromatography (HILIC) in the last few years. This is likely due to more interest in the analysis of complex analytes, which cannot be retained or separated through the standard reverse phase technique.

Those attempting HILIC often hit an immediate stumbling block when choosing a suitable scouting method. In most cases, this is the result of a few common mistakes (which can be improved upon):

- Incorrect chemistry

- Scouting gradient

- Buffer gradient & column equilibration

Let’s look at each of these in greater detail.

1) Chemistry

Historically, column manufacturers have promoted HILIC columns without mentioning the unique chemistry that underpins them. You wouldn’t see a reverse phase column without the C18 or phenyl bonded phase specification. Similarly, would people be interested in an ion exchange column without knowing if it’s a cation or anion exchanger?

For a long time, HILIC has been a slight mystery. Most experts believed that the mechanism which made HILIC work was the thin water layer that developed on the silica particle surface. Retention was then possible by partitioning analytes between the mobile phase and the water layer.

While this is mostly true, there are 2 variables to consider: water layer thickness and electrostatic interactions.

The thickness of the water layer depends on the chemistry of the HILIC column. I.e. a bare silica particle will have a different water adsorption compared to a diol column, and different from an amide column…etc

In addition to this, electrostatic and dipole-dipole interactions can occur when the analyte is partitioned on this water layer. Once again, this depends on the chemistry of the HILIC column. A diol column will provide more hydrogen binding retention compared to a bare silica column.

As per other techniques, such as reverse phase — having a range of different chemistries will increase your chances of success during method development.

| Acid | Base | Neutral | |

| Silica | Weak | Very Strong | Medium |

| Diol | Strong | Weak | Strong |

| Amide | Weak | Medium | Strong |

| Zwiterion | Strong | Medium | Strong |

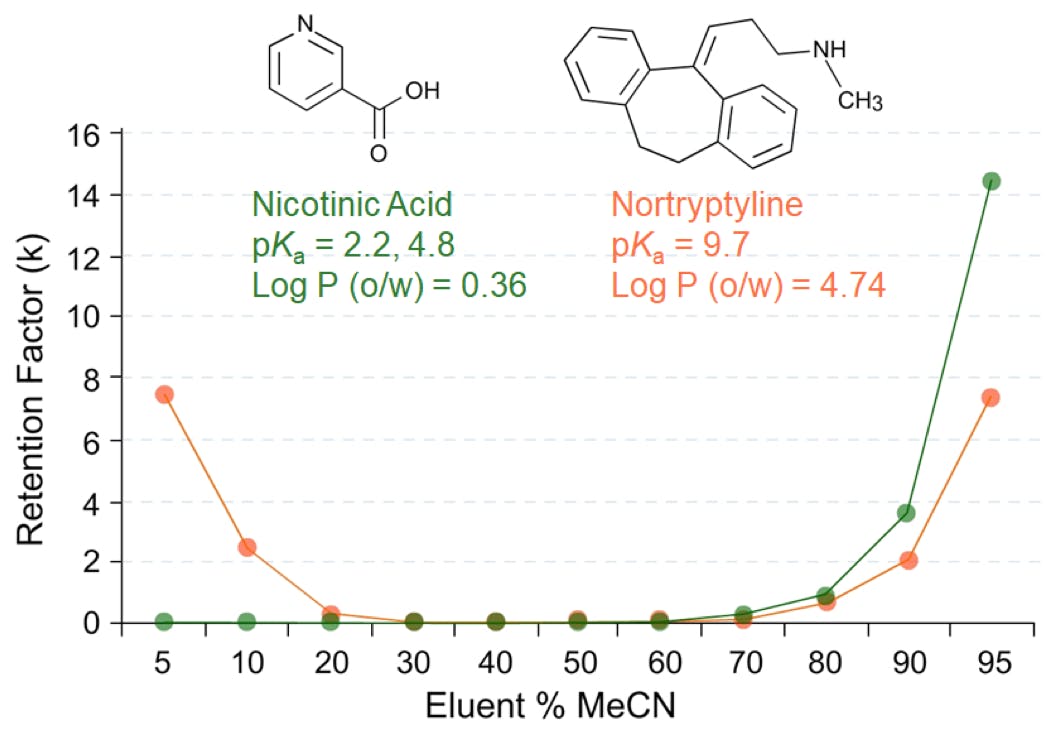

2) Scouting gradient

Another common mistake amongst HILIC newbies is performing a scouting gradient using a reverse phase mindset. In reverse phase, a scouting gradient will generally start at 5% organic and end up at 95%, or even 100%, organic. This aids the understanding of where an analyte elutes, defines if an isocratic method is possible, and which percentage of organic to use.

However, in HILIC, we cannot apply the same principle. We have to use a minimum of 3 - 5 % aqueous phase in order to generate a water layer around the particle, which is in line with reverse phase scouting gradient principle; however, we cannot go up to 90% aqueous in the column as per the previous method of developing scouting gradients. When we start encountering over 50% aqueous mobile phase going through the column, we are re-absorbing the water layers back in the mobile phase, meaning the capabilities of the stationary phase to perform HILIC are being lost. We are actually moving back towards the reverse phase mechanism.

Good method development practice in HILIC requires an aqueous scouting gradient that moves from 5% to 40%. This will also help with column re-equilibration

3) Buffer gradient & Column Equilibration

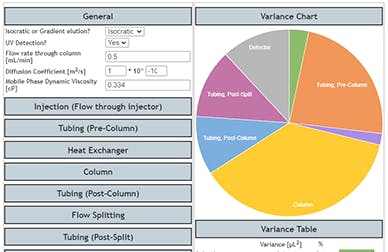

When a HILIC method is working on isocratic conditions, the column equilibration is longer compared to reverse phase but similar to working on ion exchange (also, there is no re-equilibration requirement between injections). However, when working on a gradient method, most will use the same mobile phase as they do in the reverse phase method (i.e. 100% organic in one line and 100% buffer in the other line). This means that if you change the proportion between A and B, you are also changing the overall concentration of salts going through the columns — which has a significant impact on method robustness and column re-equilibration.

This can be resolved by preparing a mobile phase which contains an equivalent level of salts, resulting in a constant concentration of salts going through the columns.

Example:

If a method is using a gradient with acetonitrile in one line and 20mM acetate buffer in the other, we can create the following mixture and achieve a constant 10mM buffer going through the column (ionic strength can be adjusted according to the chromatogram obtained).

Mobile Phase A: 95/5; Acetonitrile/200mM ammonium Acetate

Mobile Phase B: 5/95; Acetonitrile/10mM ammonium Acetate

While I fully appreciate that this is generating very specific mobile phases and increases labour time and potential waste, it also demonstrates the benefit of having combined mobile phases to improve method robustness.