03 Oct 2017

Putting the U into your UHPLC

Column fittings – you have it sorted, right? You have an array of fittings for your HPLC and UHPLC systems which are appropriate, produce zero (or negligible) dead volume and are robust and reliable.

Great – you are obviously a lot more advanced than some of the groups that I've spoken to recently – especially those using UHPLC, who frankly were a little lost regarding the best fittings to use or the impact of the incorrect use of column end fittings (yes – even after all this time!). We ourselves have struggled to the find the best options for the type of fittings to use, and the impact of not making our column unions as well as we might.

I'm going to keep this entry pretty short so that the message hopefully hits home, regarding the importance of keeping extra column volume as small as possible, especially when using UHPLC equipment.

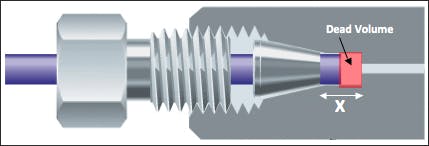

The first thing we need to note is that different manufacturers produce different column end fittings, whose internal geometry differs - sometimes markedly. One of the predominant differences is the 'stem length', shown as distance X in Figure 1, which corresponds to the length of tubing that protrudes beyond the end of the ferrule. Get this wrong and you create a significant dead volume, which is represented by the red shaded area in Figure 1.

Figure 1: Improperly fitted union/tubing in an HPLC column end fitting

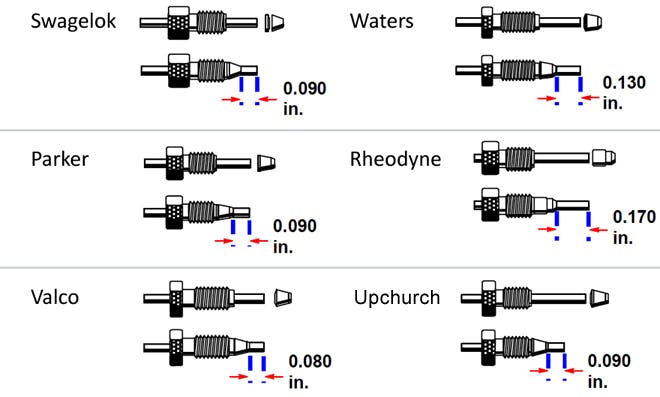

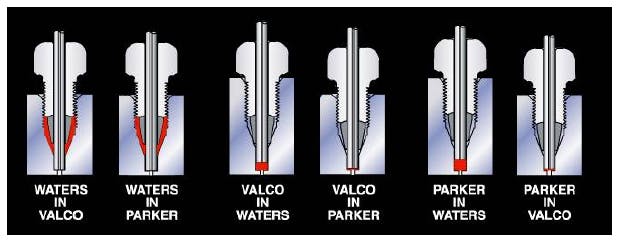

So how does one end up with a problem of this sort? If the fitting is not tight enough, or if PEEK tubing is fitted using a metal ferrule or metal tubing is fitted with a PEEK fitting, at the higher pressures encountered in UHPLC, the tubing may 'slip' causing a void within the column end fitting. If the tubing is not pushed and held fully 'home' (i.e. bottomed out inside the fitting) whilst the column connection is being made, then a void may also occur. Further, if a metal ferrule is used and over tightened in a previous column connection, the ferrule will cinch down on the tubing and not move. If the internal geometry of the fitting was different to that of the column currently being used (i.e. a column from a different manufacturer), then a void may form, or a leak will occur if the stem length is too long for the current column fitting. This re-enforces the point that, unless one uses a 'plastic' (i.e. malleable) material for the ferrule and the tubing is free to move freely within the nut / ferrule combination, then the chances of having an unwanted dead volume are high! The differences in stem length and ferrule angle and depth for various manufacturers' equipment are shown in Figures 2 and 3.

Figure 2: Required stem lengths (tubing distance past the ferrule end) for common column hardware manufacturers

Figure 3: Dead volumes created (shaded in red) when using different nut/ferrule combinations in other manufacturers column hardware

I know what you will be thinking. So what?

Well, much has been written lately regarding the overriding influence of extra column volume (dispersion) on obtaining the maximum performance from UHPLC systems. That is, the system is rapidly becoming the limiting factor in obtaining the highest possible efficiencies when using either sub 2 µm or superficially porous particle morphologies.

Let's demonstrate.

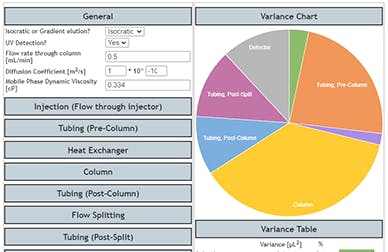

Assume a 1 mm dead volume inside a fitting which takes 1.6 mm o.d. tubing (a pretty standard tubing type). The dead volume created is around 2 µl.

The total system extra column volume within a modern UHPLC system will be somewhere between 10 and 20 µl depending upon configuration and manufacturer. So this new dead volume may contribute something in the region of 10 – 20% of 'new' extra column volume.

Again – why does this matter. Well, let's look at the overall extra volume contribution compared to the column volume.

The interstitial volume of a 150 x 4.6 mm column (assuming silica porosity factor of around 0.6 – i.e. the silica is 60% 'space' and 40% silica) is around 1.5 mL. The interstitial volume of a 50 x 2.1 mm column packed with a similar porosity material is 103 µL .

An extra column volume of 12 µL represents just 0.8% of the total system volume when a 150 x 4.6 mm column is used. However, the same extra column volume is almost 12% of the total system volume when the smaller 50 x 2.1 mm column is used!

Let's have a look at what this may mean in practice.

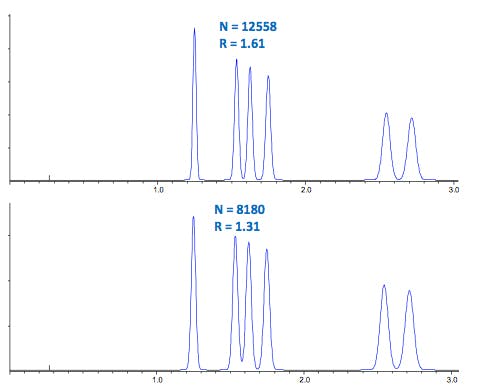

In Figure 4, the top chromatogram shows a test mix acquired on a UHPLC system with 12 µL extra column volume using a 50 x 2.1 mm column packed with 1.8 µm silica particles. The bottom chromatogram shows exactly the same separation performed on a system with 15 µL dead volume.

Figure 4: Top – efficiency and resolution (2,3) for a test mix separated on a 50 x 2.1 mm column with 1.8 µm particles using a system with 12 µL extra column volume. Bottom – the same separation carried out on a system with 15 µL extra column volume.

Peak 2 in the separation shown in Figure 4 loses 35% efficiency and is not satisfactorily baseline resolved due to an increase of just 3 µL extra column volume! A very significant issue which could easily be caused by failing to optimise the type of end fitting used or the way in which the union is formed.

So – am I saying that only a specific manufacturers' columns can be used with their equipment and column fittings? Absolutely not. However, we do need to be very mindful of the points raised above, regarding the types of fittings used, which I will summarise below:

- Metal ferrules are designed for use with a specific type of column end fitting hardware – ask your fitting manufacturer which columns will fit which ferrule types

- Metal ferrules cinch onto PEEK tubing and once immovable will not properly fit any other type of manufacturer's column – unless the end fitting hardware internal design is the same

- Metal tubing often 'slips' when used with PEEK ferrules, forming an internal dead volume within the column fitting

There are several solutions to the issues highlighted above, and you can contact your manufacturer for suggestions, however, the mixed metal/PEEK ferrules used in the design shown below (EXP fittings, Optimize Technologies, Portland, Oregon), are very useful in that they hold very high pressures, deform to the column end fitting internal volume and the specially designed titanium back ferrule does not cinch onto PEEK or metal tubing but grips very firmly on either of these tubing types whilst allowing the stem length to be adjusted to minimise dead volumes within the column end fittings.

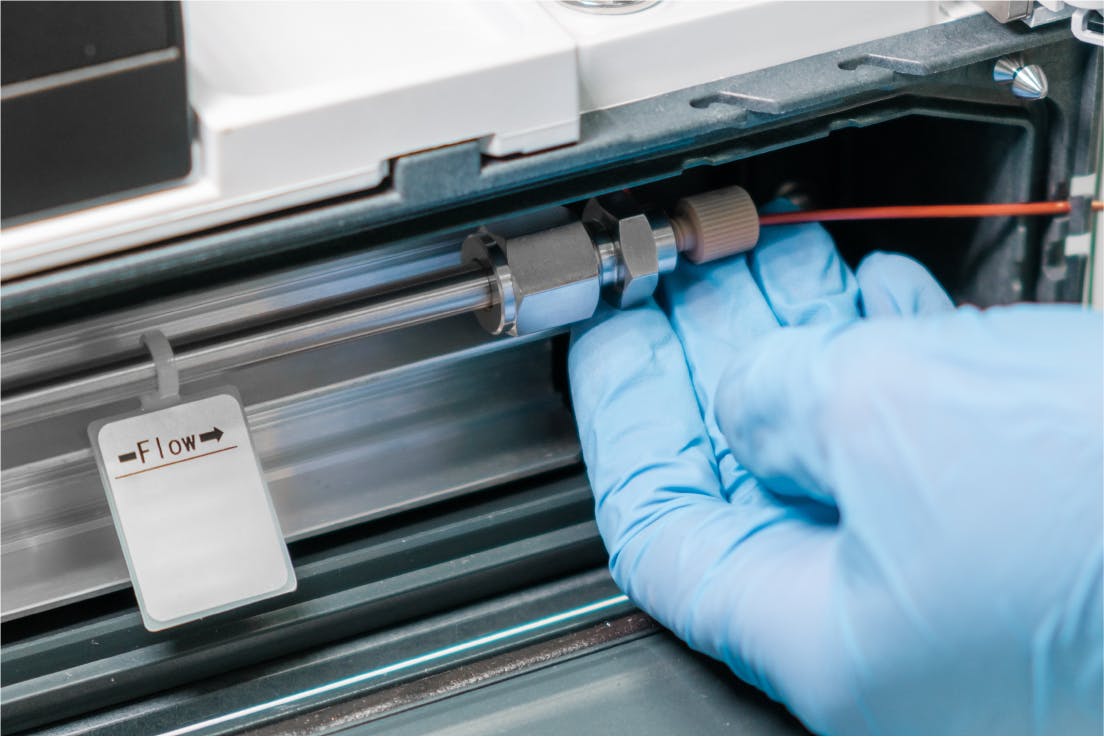

Figure 5: Hybrid Titanium / PEEK ferrule used on a fingertight nut and metal tubing for UHPLC column connections.