20 Feb 2020

Reversed Phase Method Development Made Simpler With HALO® Toolkit

Developing a reversed phase method can be challenging and time-consuming. Although there are a variety of column chemistries and technologies available, when the pressure is on to complete analysis in a restrictive timeframe, method development can fall by the wayside. This is unfortunate as newer technologies, alongside specific screening approaches, present numerous ways of maximizing efficiency.

The principles of reversed phase have not changed in the past four to five decades. However, our understanding of the mechanisms that can achieve desired separation, sharp peak shape, and enhanced sensitivity has improved immensely. For instance, we now know why and when we need well end-capped columns to minimize (or control) secondary interaction with the silica surface. We can also improve efficiency by reducing particle size at the expense of higher backpressure. So what’s an alternative way to improve efficiency without necessarily increasing the backpressure?

How Do You Improve Separations Under Time Constraints?

Chromatographers continue to push separation limits due to increasing productivity demands. But how can they improve separation in less time? Or with less solvent consumption and increased sensitivity? Or all of the above?

The specific drivers may be different, but the overall goal is the same – ‘I need more without sacrificing anything’. This dilemma isn’t new. It garnered attention back in the early 2000’s when UHPLC instrumentation first arrived on the scene. The possibility of reducing run times by up to 70% while maintaining high resolution emerged with the adoption of smaller particle size columns and new hardware that accommodated the increase in back pressure required by these smaller particles.

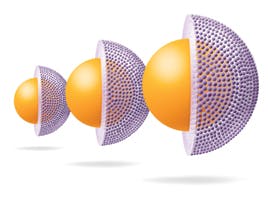

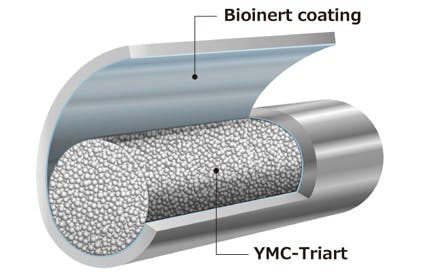

In 2006, Advanced Materials Technology took a different path towards this goal and introduced a novel technology where particles had an overall diameter of 2.7 μm with a solid silica core surrounded by a porous layer that maintained 75% of the total particle volume. Enter, the HALO® Fused-Core® particle.

HALO® Fused-Core® Technology

This little HALO® Fused-Core® particle started has become the new standard in HPLC and LCMS separations.

The higher efficiency (H) achieved by SPP columns is due to a combination of all three van Deemter terms (A, B and C). They are smaller for SPP particles.

What can we see?

• A reduction in eddy diffusion (40% smaller van Deemter “A term”) due to more uniform analyte flow paths through the column bed

• Much lower longitudinal broadening (25–30% smaller van Deemter “B term”) due to the presence of the solid core inside the particles

• Flatter van Deemter plot and higher optimum linear velocity (μopt, ∝ flow rate, “C term”) due to the shorter diffusion distances into the particles

Together, these factors determine that SPP columns achieve higher efficiency.

Classification and Characterization of HALO® Reversed Phase Options

Which HALO® phases are available for reversed phase analysis of small molecules? When should I use them?

The reversed phase HALO® phases may be classified by three main chemistry designations: alkyl, aromatic, and polar.

- Non-aromatic alkyl chemistry has the general formula of CnH2n+1. Aromatic chemistry contains one or more 6-carbon rings with the general formula C6H6. Polar chemistry contains any of the following functional groups or element: amide, cyano, or fluorine. C18, C8, and C30 are all in the alkyl designation.

- Phenyl-Hexyl, while aromatic, demonstrates alkyl characteristics. Solely aromatic is Biphenyl. PFP shares characteristics of both aromatic and polar chemistries.

- In the polar section is ES-CN.

- Finally, in the overlap section between polar and alkyl are AQ-C18 and RP-Amide. They are mostly polar but often exhibit some hydrophobic selectivity.

- When selecting screening phases for method development, it is good practice to choose phases from each main chemistry designation or from overlap sections, if necessary, to achieve your separation.

What is the Best Approach to Method Development?

The more chemistries screened, the better chance of finding the correct column. A more specific way to get started is to select orthogonal phases to optimise the chance of success.

Element is currently offering HALO® Selectivity Kits in order to support chromatographers developing methods for challenging separations. They are available for a limited time only, so now’s the time to get your hands on one. Two kit types are currently available:

- Orthogonal kit: This contains a C18, phenyl-hexyl, and RP-amide allowing for quick identification of the main separation factor required for your method.

- Shape selectivity kit: this contains a C18, C30, and PFP column. It allows improved separation of analytes based on their molecular shape.

YOu can find these products on our website or contact your local sales team for more information. The following case studies exemplify just how these kits can work practically.

Orthogonal Selectivity Case Study

A separation of paracetamol (acetaminophen) and its 14 impurities, following EP 9.4, was compared using three orthogonal phases (HALO® C18, HALO® RP-Amide, and HALO® Phenyl-Hexyl) to demonstrate selectivity differences of bonding phases. Interesting elution order changes were observed between HALO® C18 and HALO® RP-Amide. Several impurity components (in particular F and M) were retained longer on the HALO® RP-Amide column compared to HALO® C18 since RP-Amide has more retention for phenol-containing compounds.

Additionally, there was an elution order switch between impurity A and B on HALO® C18 compared to HALO® Phenyl-Hexyl. These compounds differ by only a methyl group and the position of the hydroxyl group on the phenyl ring so it is reasonable that C18 would retain impurity B more than Phenyl-Hexyl. There were two complete coelutions on the HALO® RP-Amide and HALO® Phenyl-Hexyl phases, which seem to have occurred due to these compounds being retained longer on these two phases. However, this should not be considered a discouraging result since other mixes may benefit from the selectivity of these phases. This is why having multiple bonded phases available for screening is highly recommended.

Shape Selectivity Case Study

An example of another benefit in screening different bonded phases is shown below, where HALO® C18, HALO® C30, and HALO® PFP were all used to screen the same sample of four tocopherols. While the retention was the highest with HALO® C18, there was no resolution between the beta and gamma-tocopherols. For this particular sample, shape selectivity had more impact than hydrophobicity. The highest resolution and least retention was observed with the HALO® PFP phase followed by the HALO® C30 phase. An elution order reversal was also observed between the HALO® PFP and the HALO® C30 phases.

These two examples highlight the importance of understanding your sample components and properties and the necessity for several column phases when undertaking method development.

Both kits are available on 2.7 μm, making them compatible with both HPLC and UHPLC systems, in a variety of column lengths and internal diameters.

For more information on how HALO® can improve your chromatography separations, contact your local Element rep or account manager. This promotion is valid until the end of June 2020.

Developing a reversed phase method can be challenging and time-consuming. Although there are a variety of column chemistries and technologies available, when the pressure is on to complete analysis in a restrictive timeframe, method development can fall by the wayside. This is unfortunate as newer technologies, alongside specific screening approaches, present numerous ways of maximizing efficiency.

The principles of reversed phase have not changed in the past four to five decades. However, our understanding of the mechanisms that can achieve desired separation, sharp peak shape, and enhanced sensitivity has improved immensely. For instance, we now know why and when we need well end-capped columns to minimize (or control) secondary interaction with the silica surface. We can also improve efficiency by reducing particle size at the expense of higher backpressure. So what’s an alternative way to improve efficiency without necessarily increasing the backpressure?

How Do You Improve Separations Under Time Constraints?

Chromatographers continue to push separation limits due to increasing productivity demands. But how can they improve separation in less time? Or with less solvent consumption and increased sensitivity? Or all of the above?

The specific drivers may be different, but the overall goal is the same – ‘I need more without sacrificing anything’. This dilemma isn’t new. It garnered attention back in the early 2000’s when UHPLC instrumentation first arrived on the scene. The possibility of reducing run times by up to 70% while maintaining high resolution emerged with the adoption of smaller particle size columns and new hardware that accommodated the increase in back pressure required by these smaller particles.

In 2006, Advanced Materials Technology took a different path towards this goal and introduced a novel technology where particles had an overall diameter of 2.7 μm with a solid silica core surrounded by a porous layer that maintained 75% of the total particle volume. Enter, the HALO® Fused-Core® particle.

HALO® Fused-Core® Technology

This little HALO® Fused-Core® particle started has become the new standard in HPLC and LCMS separations.

The higher efficiency (H) achieved by SPP columns is due to a combination of all three van Deemter terms (A, B and C). They are smaller for SPP particles.

What can we see?

• A reduction in eddy diffusion (40% smaller van Deemter “A term”) due to more uniform analyte flow paths through the column bed

• Much lower longitudinal broadening (25–30% smaller van Deemter “B term”) due to the presence of the solid core inside the particles

• Flatter van Deemter plot and higher optimum linear velocity (μopt, ∝ flow rate, “C term”) due to the shorter diffusion distances into the particles

Together, these factors determine that SPP columns achieve higher efficiency.

Classification and Characterization of HALO® Reversed Phase Options

Which HALO® phases are available for reversed phase analysis of small molecules? When should I use them?

The reversed phase HALO® phases may be classified by three main chemistry designations: alkyl, aromatic, and polar.

- Non-aromatic alkyl chemistry has the general formula of CnH2n+1. Aromatic chemistry contains one or more 6-carbon rings with the general formula C6H6. Polar chemistry contains any of the following functional groups or element: amide, cyano, or fluorine. C18, C8, and C30 are all in the alkyl designation.

- Phenyl-Hexyl, while aromatic, demonstrates alkyl characteristics. Solely aromatic is Biphenyl. PFP shares characteristics of both aromatic and polar chemistries.

- In the polar section is ES-CN.

- Finally, in the overlap section between polar and alkyl are AQ-C18 and RP-Amide. They are mostly polar but often exhibit some hydrophobic selectivity.

- When selecting screening phases for method development, it is good practice to choose phases from each main chemistry designation or from overlap sections, if necessary, to achieve your separation.

What is the Best Approach to Method Development?

The more chemistries screened, the better chance of finding the correct column. A more specific way to get started is to select orthogonal phases to optimise the chance of success.

Element is currently offering HALO® Selectivity Kits in order to support chromatographers developing methods for challenging separations. They are available for a limited time only, so now’s the time to get your hands on one. Two kit types are currently available:

- Orthogonal kit: This contains a C18, phenyl-hexyl, and RP-amide allowing for quick identification of the main separation factor required for your method.

- Shape selectivity kit: this contains a C18, C30, and PFP column. It allows improved separation of analytes based on their molecular shape.

You can find these products on our website or contact your local sales team for more information. The following case studies exemplify just how these kits can work practically.

Orthogonal Selectivity Case Study

A separation of paracetamol (acetaminophen) and its 14 impurities, following EP 9.4, was compared using three orthogonal phases (HALO® C18, HALO® RP-Amide, and HALO® Phenyl-Hexyl) to demonstrate selectivity differences of bonding phases. Interesting elution order changes were observed between HALO® C18 and HALO® RP-Amide. Several impurity components (in particular F and M) were retained longer on the HALO® RP-Amide column compared to HALO® C18 since RP-Amide has more retention for phenol-containing compounds.

Additionally, there was an elution order switch between impurity A and B on HALO® C18 compared to HALO® Phenyl-Hexyl. These compounds differ by only a methyl group and the position of the hydroxyl group on the phenyl ring so it is reasonable that C18 would retain impurity B more than Phenyl-Hexyl. There were two complete coelutions on the HALO® RP-Amide and HALO® Phenyl-Hexyl phases, which seem to have occurred due to these compounds being retained longer on these two phases. However, this should not be considered a discouraging result since other mixes may benefit from the selectivity of these phases. This is why having multiple bonded phases available for screening is highly recommended.

Shape Selectivity Case Study

An example of another benefit in screening different bonded phases is shown below, where HALO® C18, HALO® C30, and HALO® PFP were all used to screen the same sample of four tocopherols. While the retention was the highest with HALO® C18, there was no resolution between the beta and gamma-tocopherols. For this particular sample, shape selectivity had more impact than hydrophobicity. The highest resolution and least retention was observed with the HALO® PFP phase followed by the HALO® C30 phase. An elution order reversal was also observed between the HALO® PFP and the HALO® C30 phases.

These two examples highlight the importance of understanding your sample components and properties and the necessity for several column phases when undertaking method development.

Both kits are available on 2.7 μm, making them compatible with both HPLC and UHPLC systems, in a variety of column lengths and internal diameters.

For more information on how HALO® can improve your chromatography separations, contact your local Element rep or account manager. This promotion is valid until the end of June 2020.