15 Aug 2019

Vials vs 96-Well Plates

96-well plates are standard tools in analytical research and clinical diagnostic testing laboratories. They’re most commonly used in the enzyme-linked immunosorbent assay (ELISA) and the polymerase chain reaction (PCR) — the basis for most modern medical diagnostic testing in humans and animals. Well plates come in various formats, such 384-well plates.

Chromatographers still use colossal amounts of various vials and caps. But why is this the case? At what point could, or should, you switch to a 96-well plate?

Technique & Application

Which Chromatographic technique is in use? Understand this before selecting a container for samples.

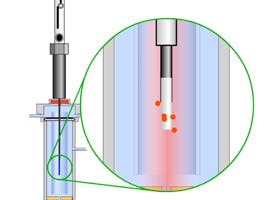

When using GC or GC-MS, look for volatile compounds, that require containers to have a good seal. In this case, prioritise the use of crimp cap vials, which will remain tightly sealed after injection.

With this in mind, 96-well plates are unlikely to be a useful format for GC work. For LC work, where analytes are less volatile and an internal standard can compensate for some solvent evaporation, 96-well plates can be an excellent solution. They can save time and money on specific applications.

Sample preparation sometimes requires evaporation steps and 96-well plates make this easier to control in comparison to vials. The Porvair MiniVap and MiniVap Gemini optimise this with ease.

The Porvair MiniVap Gemini

For sample preparation, most manufacturers include solid-phase extraction (SPE) and supported liquid extraction (SLE) compatible with a 96-well plate format.

Cost Comparison

There are two costs associated with sample storage for injection — the container and the closure. When using vials, there are three common types of closure:

- Screw caps

- Snap caps

- Crimp caps

For help with troubleshooting common problems with vials, watch our helpful video.

They each come with features and benefits, reflected by different costs. Regarding plates, there are also different types of Closure system:

- Silicone mats (various types)

- Polymer seal (using a plate sealer)

- Aluminium foils (using either a plate sealer or adhesives).

There are a few different options of silicone mats. The choice depends on whether plate content is stored or injected. A pre-slit mat allows injection from the plate and the container to be resealed after injection.

Polymer seals or aluminium foils are cost-effective, once the cost of the plate sealer is offset. However, they can be inconvenient as the plate is not sealed after injection. This is generally a great option for labs with very high throughputs, which go through more than 20 plates of samples a day.

Comparing the cost of 96 vials and caps and a 96-well plate (with either closure option) the well plate is kinder on budgets.

Labour and time

When preparing samples for injection, the various steps (liquid transfer, mixing, centrifugating, etc) generate human errors such as sample inversion and cross-contamination.

96-well plates make these errors less likely as all samples are transferred at once in their plates. Adding an internal standard, buffers, mix/centrifuge, etc will have no impact on sample placement. Additionally, any transfer from one plate to another can be controlled using 8-channel pipettes or 96 heads instruments. This reduces the risk of costly errors.

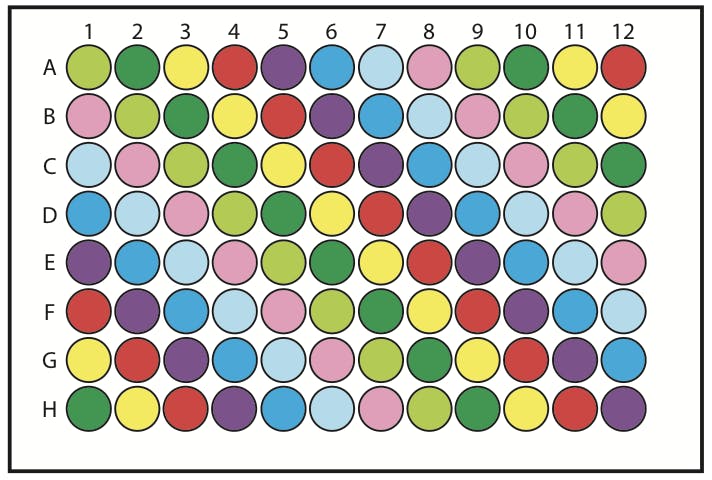

One difficulty with the use of 96-well plate is visibility. As they are made of polymer, they are opaque making it difficult to see where each sample should go when transferring many. There are two solutions to this, either spend big on automation or adopt a colour coding methodology. Colour coding could save you a lot of money.

Visibility isn’t an issue with a liquid handler system, as long as it’s programmed correctly and samples are placed in the right locations. Obviously, hundreds of thousands of pounds aren’t always available to acquire such instruments; however, there is a trick that aids visibility when transferring samples.

Click the image below to print off a PDF template to place underneath a 96 well plate.

Conclusion

While vials and caps will remain to be used for a large number of applications, such as GC, 96-well plates are a great alternative that reduces the cost of high throughput analysis. However, for most labs, benefiting fully from the use of 96-well plates requires a small to medium investment (from 8-channel pipettes to various liquid handler).

Analytes binding to polymer is a final consideration, as it can occur more than with glass containers. This can lead to variability and recovery issue, meaning vials are still be a viable alternative.

Find out more about a range of 96-well plates on our website.