19 Aug 2019

The art of packing columns for low pressure liquid chromatography

Low-pressure liquid chromatography is predominantly used for the separation of biomolecules on a laboratory scale. When using low-pressure liquid chromatography systems, pre-packed columns offer convenience and peace of mind. The column is packed well and working within certain tolerances to give reproducible chromatography. However, there are many reasons to pack columns on-site. For instance, cost and flexibility.

Packing a column is distributing all the particles in a reproducible, homogenous packed bed. Since the art of column packing is often passed down informally from one lab member to another, bad habits occur that can result in poor packing. This may have a detrimental effect on the final yield of purified biomolecules.

There are ways to ensure a well-packed column that produces consistent chromatographic results. There are also ways to monitor column performance for both pre-packed and self-packed low-pressure liquid chromatography columns.

Figure 1) Typical lab-scale glass column used for low-pressure liquid chromatography - find YMC glass columns here

Column Hardware

Although all lab-size columns are similar (Figure 1) there are variations between the quality and flow characteristics between different manufacturers. Look out for how the liquid is delivered onto the column when choosing hardware. The uniform delivery of the sample onto the column is crucial for good chromatography.

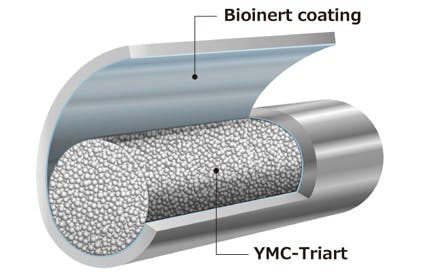

Some column hardware uses a coarse woven mesh in between a finer particle retaining net. This type of hardware has a high-lateral permeability to distribute the incoming liquid within the support structure before it enters the packed bed space. This is believed to help distribute the liquid from the central flow rapidly and uniformly over the full surface area of the net and packed bed to give optimal flow characteristics. However, it has downsides. It’s tricky to fit and can sometimes become detached due to clogging or air bubbles.

Other glass column producers have created column hardware without nets by using innovative frits designed with improved flow characteristics to channel the liquid evenly across the top of the column. This combines the ease of using a frit with the flow characteristics required for reproducible chromatography. The mechanism by which the pistons move through the column is also important to consider.

Vertical adjustment for column compression can be easier to use but often disturbs the column packing at the top of the resin and results in a less homogenous packed bed. In comparison, axial compression can compress the column bed without disturbance but may take a little more time to complete adjustment. Also, consider if there’s potential to scale-up with the same manufacturer for pilot column hardware.

Another thing to consider is how flexible the manufacturer is and whether they can accommodate future needs (for example, by providing custom specifications or user-friendly scale-up options).

Resin Preparation

It is important to prepare the resin slurry by following the manufacturer’s instructions. Neglecting to follow this may result in incomplete homogenisation of the resin which will cause differences in packing density within the column bed. It should be re-suspended in the packing buffer and the resin should be allowed to settle. The settled resin volume should then be adjusted to the required concentration (usually 30-50 % - as per the manufacturer’s recommendation) by adding or removing the packing buffer. The slurry can then be carefully and gently resuspended by stirring carefully but thoroughly before column packing.

Column Packing Tips

- Ensure the total volume of the column can contain the whole slurry volume. If it isn’t, add a reservoir column on top.

- Ensuring the column is levelled prior to packing will ensure a level column and good even distribution of fluid onto the column.

- Wet the bottom frit with buffer and allow the buffer to drain to remove any air bubbles.

- The resin should be poured along the walls of the column to prevent air bubbles being trapped.

- Once assembled slowly increase the flow rate to the final recommended column packing rate. This should prevent shock to the column bed that is forming and avoid having to unpack the column due to uneven packing.

- Once the resin has been packed under flow and no further changes are seen, the piston can be adjusted to the required position with care to not disturb the resin bed. This step is where radial rather than vertical adjusting columns can be a real benefit.

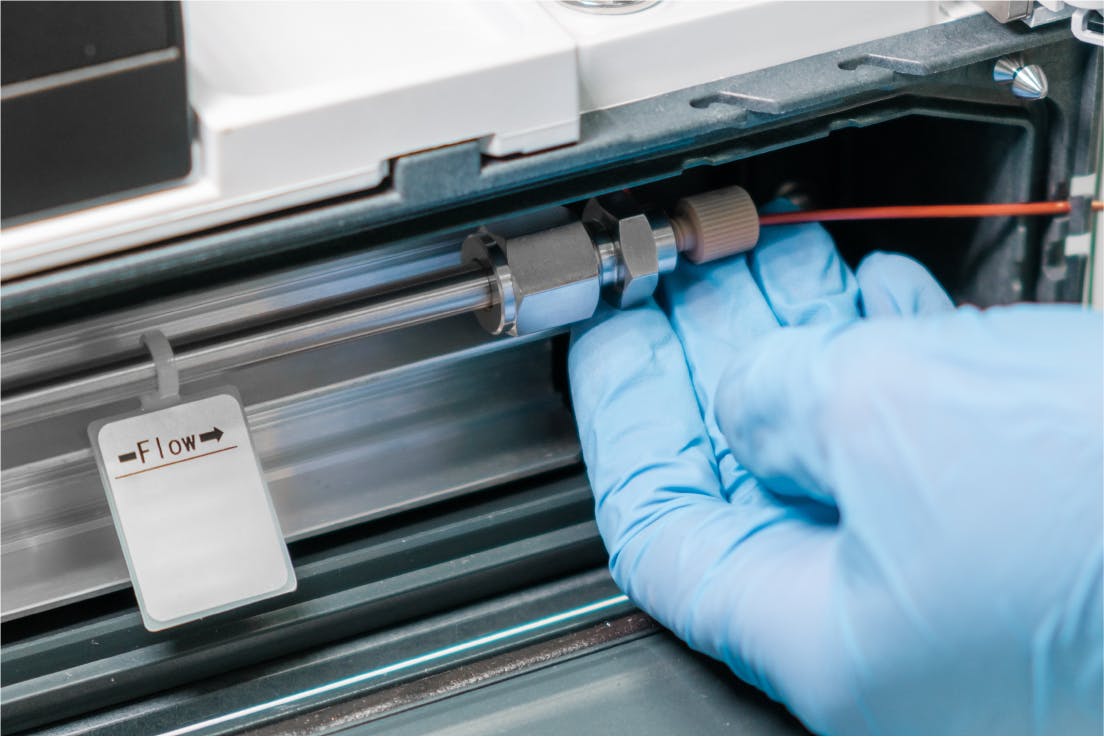

Evaluating Column Packing

Rather than moving straight onto a real sample once the column is packed, save time in the long run by evaluating the packing quality of the column. This will ensure reproducible results and ensure the maximum recovery of biomolecules. Column efficiency testing is a way to monitor packed bed performance and can be referred to between runs to check for changes of the bed integrity. This helps inform when column repacking is necessary.

Efficiency is a mathematical measure of the broadening of a chromatographic peak as a function of time (Figure 2). The more efficient a separation, the narrower the peaks, and the easier they are to detect from baseline noise. One way to measure efficiency determines the number of theoretical plates generated by a column. The plate number (N) provides an effective number of analyte/stationary phase equilibration sites. What defines a good plate number per column length will vary depending on the resin used and is usually stated for each in the manufacturer’s recommendations.

Where:

tr = Peak retention time

wb = Peak width at baseline, as determined by dropping two tangents at the inflexion points and intersecting the baseline

w½ = Peak width at half peak height

N = Theoretical plate number

Figure 2) Calculations to measure theoretical plate number

Another parameter to monitor the performance of the column is the peak symmetry for test compound as this can report on the “health” of the whole system. Deviations from an ideal Gaussian-shaped peak (AS = 1) may be caused by irregularities in the packed bed itself, but also by unfavourable fluid flow within tubing and components external to the packed bed. In addition, peak asymmetry may arise from air trapped within the column or from clogged frits or screens in the fluid distribution system, resulting in flow disturbances. A typical range to aim for biomolecule separation is 0.8 < As <1.8 and evaluating the start of the column lifetime allows you to evaluate the system between runs which can aid in troubleshooting.

Figure 3) Diagram showing how to measure peak symmetry at 10 % of peak height to evaluate column performance.

Using a Packed Column

Once the column is packed and the necessary checks to confirm it is working optimally have been completed, move on to separating biomolecules of interest. However, it is worth remembering that anything that disturbs the column bed, such as air bubbles, column clogging, or significant pressure spikes will require the column to be repacked. Not doing so may result in less than ideal chromatography and reduced recover of the biomolecule from the column.

References

https://bitesizebio.com/31648/pack-a-column-like-a-pro/

https://doi.org/10.1016/B978-012374023-6.50013-0

CHROMacademy: Theory and Instrumentation of GC - Chromatographic Parameters - Peak Asymmetry

CHROMacademy: Theory and Instrumentation of GC - Chromatographic Parameters - Efficiency