26 May 2021

Taking steps to a reduced Eco Footprint and a safer lab environment

By Victoria McOuat

During the global pandemic, and specifically through the large scale “lockdowns” across most countries, the impact that we have on the world around us has been difficult to ignore. Across the world, there has been a significant improvement of air quality, reduction of Greenhouse gas emissions, water, and noise pollution1. For April 2020, the European Environment Agency stated that NO2 concentrations were almost 40% lower across Europe than expected, the UK being 45% lower, France 52% and Spain 61%2! One of the most publicised examples of this change is Venice where the previously murky waters have been clear, with fish and wildlife starting their return to the area3. The relatively short time it has taken for these changes to become clear has really highlighted the significant improvement that can be made with everyone working together.

Figure 1: Venice Canal before and after lockdown in the city3

Let us be realistic though, this is a temporary situation, people need to travel, factories need to produce, and as life will go back to normal, pollution levels will rise along with it. While many people are conscious, and proactive, of the steps they can take at home, improvements in the workplace can be even more important. A study looking at the carbon footprint of a clinical lab (considering only electricity, water, gas consumption, and [plastic and paper] waste production) showed that optimising operations and basic facilities could reduce a lab’s environmental impact by ~50%4. This is not even taking a focus on the solvent side of things, arguably a significant factor for many labs.

Most are aware of the general improvements we can make at home and in the lab - shutting down computers/instrumentation where possible, switching off lights when we leave a room, reducing water consumption, recycling, etc. However, there are a great variety of “small steps” that you can take to reduce your labs’ impact on the environment, and to improve your lab environment for your own health and wellbeing. Every little effort makes a difference, and they all add up. We’ve pulled together some examples that will hopefully get you thinking about improvements that you can make to reduce the environmental impact of your lab and to improve the lab environment too.

Recycling

Many people are unaware of the range of recycling programmes that are now available. From baby food pouches to medicine blister packs5, many organisations are working towards that ideal circular economy. Now, there is even a Kimtech™ Nitrile Glove recycling programme6, designed with users in Pharmaceutical/Bioscience manufacturing companies, research facilities and universities in mind. At the moment, they only accept their own brand gloves, but it is likely others may follow their example.

Much of the glassware used for the supply of chemicals, and even some plastic and aluminium bottles, can also be recycled7. So long as they have been sufficiently rinsed, no residue is left and the bottles are dry, most waste handlers can collect as non-hazardous waste and recycle. It is always a good idea to have a chat with your waste management service to see what options they can offer and what their own conditions are.

Solvent safety and consumption

Working in chromatography, and in many labs, one big safety concern is always solvents. If you have ever been involved in risk management, you might be familiar with the acronym “Eric Prevents Death”. Eliminate, Reduce, Isolate, Control, PPE, Discipline. Elimination of solvent handling is not an option in a lab environment (not yet anyway) so we do what we can to reduce our exposure. We minimise how often we handle solvents, how much and what type we are working with, we use fume cupboards, extraction arms, gloves, etc. and there have been some great advancements in technology to really reduce the volume of solvent we need to use.

Liquid-liquid extraction techniques can be far from ideal. They often require the use of large volumes of solvent, they are very time consuming, and when you are getting into the region of a 1 litre total volume with a few minutes of shaking, repeat x40 it’s tiring! If you’ve ever spent a significant amount of time on this technique, you might be just as excited as I was when I learned about DiLLME. Dispersive Liquid-Liquid Micro Extraction carried out by an automated robotic workstation, with the option to be combined with chromatographic systems. Extraction solvent volume can be reduced to under 1ml, a massive impact on solvent consumption as well as exposure, not even thinking about the time saved! By automating the technique reproducibility can be dramatically improved too8.

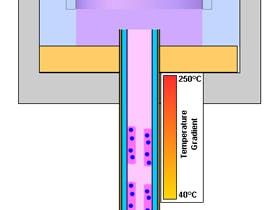

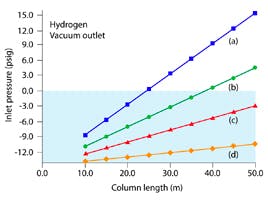

Figure 2: DiLLME example with GCMS set up by Anatune

When working with liquid chromatography, chances are the eluent you are using will contain some amount of toxic solvent. Having extraction capabilities near your instrument might not be possible or practical and would certainly come with a hefty price tag. Additionally, extraction and air circulation systems have their own cost, one fume hood alone can use as much energy as up to three homes per year9. A great way to conserve energy is to ensure fume hood sashes remain closed when not in use, but this doesn’t help for our eluent and waste on our instrument.

Instead of trying to remove solvents leaching into the atmosphere, we can stop it happening. And I am sorry, but the answer is not Parafilm. Safety caps for eluents and waste are available in a variety of forms, some companies even have them as part of their safety regulations10. These products can prevent solvents from leaching into the air and as an added bonus you will have increased long-term mobile phase consistency. On your eluent, they provide an airtight seal preventing evaporation of solvents into, or contamination from, the atmosphere and on you can get larger charcoal filters for waste bottles. You will find options from most chromatography manufacturers, many offering replacement indicators to ensure they remain effective, such as the Stay Safe cap below. S.C.A.T.™ Europe (Safety Center for Analysis Technology) was founded directly to protect lab users from harmful substances in the workplace11. They have the world’s most complete system for both eluents and waste containers and develop their products together with chemists, engineers, and technicians. Both of these solutions are available through Element so contact your local Account Manager for more information.

Figure 3: Left: S.C.A.T™ Safety Cap and Safety Waste Cap, Right: Agilent™ InfinityLab Stay Safe cap

Conscientious product selection

In your own day to day life, you might find yourself making ethical decisions on the products you select. You might have a refillable bottle for your water, try to use products that are recyclable or compostable, and you might choose to buy from companies who are more active in their environmental action. So why shouldn’t you do this in the lab too?

You will find that some manufacturers may offer recycle options on product such as gas filters, so find out what your suppliers have available. Placing bulk orders and standing orders to reduce the frequency of deliveries along with optimising the pack sizes you order to minimise packaging can help too. Your Element Account Manager will be able to help with recommendations here if these options are of interest. Most manufacturers will have a visible Environmental Policy & Social Responsibility, so check them out. You can even find promotions such as the recent one from AMT for their HALO Enviroclass range. For every one of their PFAS or PAH columns sold they were planting two trees!

And if planting trees is your thing, then you might have heard of Treeapp™ or even already be signed up. Treeapp™ offers users the option to watch advertisements to earn credits and plant trees to offset their own carbon footprint. As well as the advertising option, which might not be appropriate for many labs, they do offer a Planting and offsetting option for businesses12. You can buy “carbon credits” either by offsetting based on business activity and number of employees, or by how many trees you want to plant. You will then get certificates for your achievements and you even get to choose where the tree planting funds are allocated. Along with mitigating climate change, planting trees helps to regenerate degraded areas, create habitats for native species and create income and opportunities for rural communities.

Hopefully, this has given you some ideas on how you to improve your lab environment. And to start thinking about how your lab, or your organisation, can work toward minimising its environmental impact.

If you’re interested in any of the options discussed here you can get in touch with your account manager directly, or contact [email protected] and they will get back to you, if you want to reach our colleagues at Anatune please use [email protected]

References

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7498239/

- https://www.eea.europa.eu/publications/covid-19-and-europe-s/covid-19-and-europes-environment

- https://www.snugme.com/venices-crystal-clear-canals-teem-with-fish-birds-after-lockdown-reveals-that-people-have-been-their-virus/

- https://www.researchgate.net/publication/328912057_Carbon_Footprint_Modeling_of_a_Clinical_Lab

- https://www.terracycle.com/en-GB/brigades

- https://www.terracycle.com/en-GB/brigades/gloves

- https://www.tradebe.co.uk/chemical-bottle-recycling

- https://www.anatune.co.uk/resources/featured-products/dillme/

- https://www.frontiersin.org/articles/10.3389/fbuil.2019.00146/full

- S.C.A.T. Do not play with Safety

- https://scat-europe.com

- https://business.thetreeapp.org/