08 Oct 2019

GC Analysis Checklist

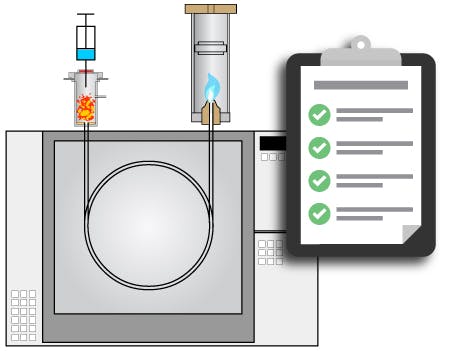

We commonly encounter troubleshooting exercises where a more in-depth knowledge and pragmatic approach to GC set-up would have been advantageous. This prompted us to produce a GC/GC-MS preparation checklist. Reference this prior to analysis to understand the actions, checks, tools, and consumable items that are required.

| Check gases are of the correct purity (99.999%+). Turn on the cylinders. If cylinder bottle pressure less than 30 psi replace it. If the line pressure (second regulator stage or gauge at the bench) is below 80psi increase line pressure with a cylinder and/or bench regulator. |

| Verify correct gas traps are installed. Verify that the gas filters are not exhausted and check when they were last replaced. |

|

Comments;

|

| Is the GC column fit for purpose? Has it been properly stored (out of sunlight with column ends capped)? How did it perform last time it was used – check records? |

| Remove the inlet septum cap. Replace the inlet septum. |

|

Comments;

|

| Open the inlet. Inspect the inlet liner and check for cleanliness including solid debris, discolouration and dark patches of burned on matrix contaminants. If in doubt replace the liner– check that the liner geometry/packing is appropriate for your method. Use a fresh liner o-ring as necessary. Replace the inlet bottom seal if necessary (follow manufacturer’s instructions). Ensure that inlet surfaces and seals are included in medium-term maintenance / replacement schedules. |

|

Comments;

|

| Replace nuts and ferrules on each end of the column. |

|

Comments;

|

| Trim the ends of the column and inspect with a magnifier or low power microscope to make sure the cut is straight and there are no rough edges. The quality of the column cut is directly related to peak shape and quantitative reproducibility, therefore good column cutting technique is essential. |

|

Comments;

|

| Note your manufacturers recommended column insertion distance (inlet and detector). Wipe the outer column surface of the column ends with a solvent suitable for removing contamination from fingerprints (isopropyl alcohol is a popular choice). Adjust the nut/ferrule position and hold in place with the ¼ septum from 6. |

|

Comments;

|

| Insert the column into the inlet. Tighten the ferrule and gently pull the column to check if the fitting is tight enough. Grip the column and continue to tighten about 1/8 turn until the column can't be moved. Repeat with the detector connection. |

| Input column dimensions, carrier gas type, required flow rate and whether constant flow/constant pressure is to be used into the instrument. Verify column flow at the detector using an electronic flow meter |

|

Comments;

|

| Switch on the inlet and detector heaters, and the detector gas flows. Ignite the detector if it is flame based. |

|

Comments;

|

| Purge dissolved oxygen by allowing carrier to flow through the column at ambient temperature for 10 – 30 mins. depending upon column dimensions. This step is important and should not be omitted. Failure to purge the phase may lead to unnecessary column damage and increased thermal equilibration times. |

| Set the oven to the conditioning temperature - 10°C above the maximum oven temperature of your method or at the gradient upper-temperature limit of the column, whichever is lower. Allow to thermally condition for the period recommended in the guide below. |

|

Comments;

|

| Cool the oven to starting temperature of your analysis. |

| Load the test method into the GC / data system. Check the split flow at the split outlet port using an electronic flow meter. Check the septum purge flow using an electronic flow meter. Perform at least 1 full temperature program according to your analytical method. |

|

Comments;

|

| Perform a test injection/system suitability test to check method performance. |

|

Comments;

|