21 Jun 2021

Your solution for large-scale SPE purification: E-PAK

By Gilles Beck

How is a known impurity eliminated from an extract or a synthesis reaction in a production scale process?

This question came up a few months ago, on one of our sample preparation courses. Depending on the chemical nature of the impurity and its similarity to our analytes, this can be a real challenge. Selectivity is what we are after in this case, and the most selective sample preparation technique is arguably Solid Phase Extraction (SPE).

The fundamental principle of SPE is to trap an analytical target on a sorbent by a catch & release mechanism that is as selective as possible. Ion-exchange (IEX) or mixed-mode (combining IEX and hydrophobic retention) mechanisms are commonly used due to their specificity.

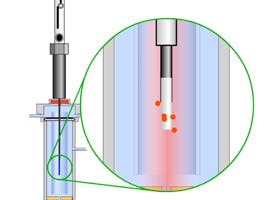

SPE protocols are complex (no less than 6 steps) and method development can be lengthy (here are some common SPE mistakes). Moreover, the practical aspect of running an SPE method can be further complicated by large sample volumes. When the sorbent is immobilized in a cartridge, as it often is, a reservoir can be held above the cartridge to accommodate the required sample volume. For instance, up to 5L of water can be processed this way when the analytes are present as traces and that sensitivity target levels are hard to reach. In this case, compounds of interest are retained on the sorbent and concentrated in the eluate. Interferences remain in the flowthrough, in a strong wash solvent or, eventually, on the sorbent. This is retentive SPE. Figure 1.

Figure 1: Retentive SPE - catch and release of molecules of interest. Source www.chromacademy.com

What if it was easier to retain the impurities rather than the targets?

Surely, if the interferences can be specifically trapped and we are not necessarily interested in concentrating our analytes which remain in the flowthrough, this must be a valid option? This is a simplified one-step process known as non-retentive SPE. Figure 2.

Figure 2: Non-retentive SPE – impurity scavenging.

Source www.chromacademy.com

Dispersive SPE (dSPE) is an interesting non-retentive approach. dSPE consists of adding an insoluble sorbent to our samples (usually bulk functionalized silica beads) on which interferences are trapped and which can eventually be eliminated. dSPE is routinely used in food testing (QuEChERS second step) and commonly used by organic chemists when catalysts must be removed from their working solutions. Recently, this became increasingly important in the pharmaceutical industry too, as regulatory agencies have increased their focus on the presence of heavy metals in formulations.

Eliminating dSPE sorbents from analytical scale solutions can be as simple as a quick spin on a benchtop centrifuge or a couple of filtrations and washes on appropriate membranes. Everything tends to be more complex (and hazardous) when dealing with large volumes. This is where Radial Flow Chromatography (RFC) can help.

All analytical and preparative columns we use today are axial flow columns where very efficient separations are often achieved at the cost of high backpressures. RFC differs from axial chromatography in the sense that the mobile phase is distributed on the outer surface of the column cylinder and radially migrates through the bed towards the center where eluents are collected.

Figure 3: Axial vs radial chromatography.

Axial

- High efficiency, analytical and PREP HPLC columns are axial

- High pressure drop when scaling-up can affect target stability

Radial

- Low pressure, compatible with higher flow rates

- Higher throughput, important for large batch volumes (manufacturing)

- A common catch & release application: Protein A for monoclonal antibodies

- NOT suitable for analytical scale due to its low efficiency

As a rather old separation technique (c.1950s) RFC was long forgotten until it was re-discovered in the 1990s for protein analysis and purification. It is now mostly used in biopharmaceutical manufacturing for affinity and IEX chromatography applications. Together with the low pressure drop, the major benefit of RFC is to dramatically increase the surface area available for chemical interactions and minimize the bed depth. This is highly desirable for catch & release mechanisms, including SPE, where lower linear velocities (the volumetric flow rate per unit of cross-sectional area of a column) promote target retention on the sorbent and allow higher flow rates without dramatic efficiency drops. Also, scale-ups in RFC are facilitated due to the linearity of the technique.

What if SPE sorbents were immobilized in RFC columns?

Our Canadian partners, SiliCycle, recently introduced E-PAK cartridges which can be packed with different sorbents and operated as RFC columns. Popular applications include large-scale scavenging of catalysts during API manufacturing or pigment removal from large volume plant extracts. But any interference could be eliminated from large samples using E-PAK.

So where to start?

Before thinking big, let’s gather information about our interferences and identify promising sorbents for an efficient sample clean-up. This is a typical dSPE screen where different bulk sorbents are added to different vessels containing our test solutions (say, 100g of API with palladium catalyst Pd) for an hour under agitation. The idea here is to determine the best sorbent and the amount needed (w/w) for optimal Pd removal (sorbent usually in excess). Let’s say that we need 20g or 20% of scavenger DMT and recoveries for our main product are acceptable.

Then pick a lab-scale E-PAK cartridge (5 x 1 cm, 8g) packed with the most efficient sorbent (DMT in this instance) and evaluate the efficiency of the scavenging reaction on a 40g API solution (the sorbent/API ratio is kept at 20%). Monitor API recoveries and Pd content. Evaluate the impact of a second pass on the cartridge. Just like in axial chromatography, the flow rate is defined by the bed volume; no need to push the flow rate too high at this point. Once the retention mechanism is established, then the method can be optimized and the flow rate increased.

Thanks to the RFC process and its linearity, the scale-up is facilitated. It is easy to select the correct cartridge geometry once the correct sorbent amount is determined. Take a look at the below chart — from our 8g lab cartridge, to an industrial scale cartridge packed with 19L of slurry, there’s only 3s of residence time difference! The pressure drop is well below 10 bar (typically between 1 -3 bar). And the dSPE sorbent, immobilized in the E-PAK cartridge, is easy to dispose of, together with the interfering molecules or impurities! No need to manipulate or filter the extract. No contamination to fear. No H&S concern. Simple!

Figure 4: Performance during scale-up.

It is fair to say that the range of E-PAK sorbents currently available represents a fraction of traditional SPE chemistries. But E-PAK functionalities include popular scavengers and IEX too. Activated charcoal has also proven to be very efficient for the clean-up of complex biological extracts.

Figure 5: E-PAK cartridges and sorbents.

Do you have a large scale SPE application? Get in touch, we’ll be happy to help.