01 Mar 2021

Water immiscible solvents as sample diluents in HPLC

Many of us have faced the situation where we have analytes which vary widely in their polarity or LogP(D) values and encounter issues with analyte solubility when choosing a suitable sample diluent for our HPLC analysis. The more polar analyte will favour aqueous solvents and the less polar will be more highly soluble in organic solvents – so which do we choose?

We often plump for an intermediate solvent such as 50:50 Water:Acetontrile (or Methanol) to make the diluent as favourable as possible to ensure all analytes as fully dissolved as possible prior to analysis. However, this is often where we run into problems with peak shape deformation of early eluting peaks especially when gradient HPLC is employed. There is also the possibility that neither acetonitrile or methanol are able to solubilise the hydrophobic analytes of interest. Further, we may have an organic eluent from a sample preparation technique which we wish to inject directly into our HPLC without risking drying down and re-constituting in an aqueous based diluent (solvent exchange). What are our options under these circumstances?

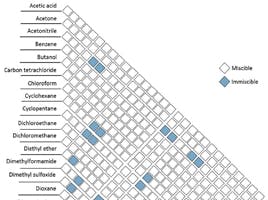

Well, contrary to popular belief, it is possible to use water immiscible solvents or solvent combinations as injection solvents when the solubility of analytes is limited or if we wish to introduce an organic extract directly into the HPLC system, however there are a few basic rules that we need to follow for successful analysis.

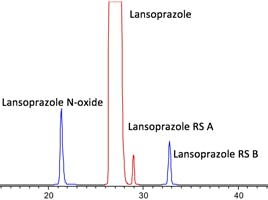

So, let’s start by examining the so called ‘general elution’ problem where we need to dissolve our analytes in a diluent which contains a higher proportion of organic solvent than the mobile phase at the start of the gradient.

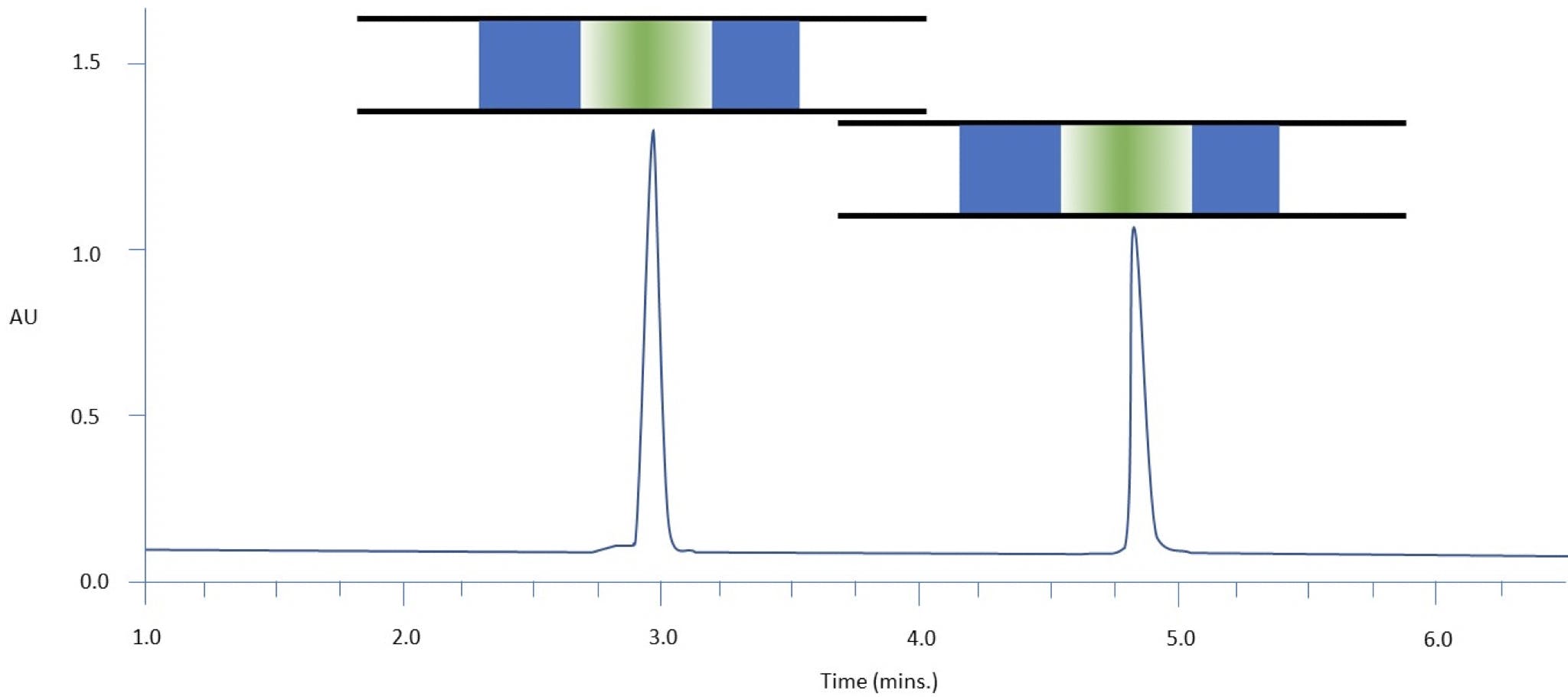

Figure 1: Separation of two model analytes using reversed phase HPLC: C18 100 x 2.1 mm, starting gradient composition 90:10 aq: MeCN for 1 minute followed by linear gradient to 70% MeCN in 12 minutes: Column representations; Green – analyte band / Blue – weaker solvent: sample diluent 90:10 aq: MeCN: injection volume 10μL.

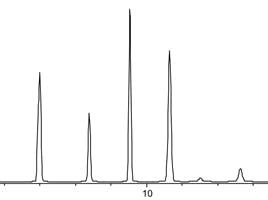

Figure 1 shows two model analytes during ‘ideal’ gradient analysis circumstances. Here the diluent has the same or lower elution strength than the starting composition of the eluent in a gradient analysis. For example, if the eluent composition at the start of the gradient is 90:10 Water: Acetonitrile, then the diluent will contain 10% or less acetonitrile by volume. As the sample plug is injected into the HPLC system and enters the column, and the sample diluent and eluent mix, then the elution strength of the solvent environment for each analyte will be approximately equal. The analyte will travel through the column and there will be no solvent based driving force for peak broadening or splitting and this is the ideal situation for gradient HPLC analysis. For clarity, all of the other intrinsic band broadening processes associated with HPLC will still be in play, however there will be no further, solvent based, band broadening.

As I’ve explained above, there are several circumstances in which this ideal situation cannot be achieved and often we need to increase the ‘elution strength’ of the sample diluent above the composition of the starting gradient. This situation risks both peak broadening and deformation, especially for earlier eluting analytes.

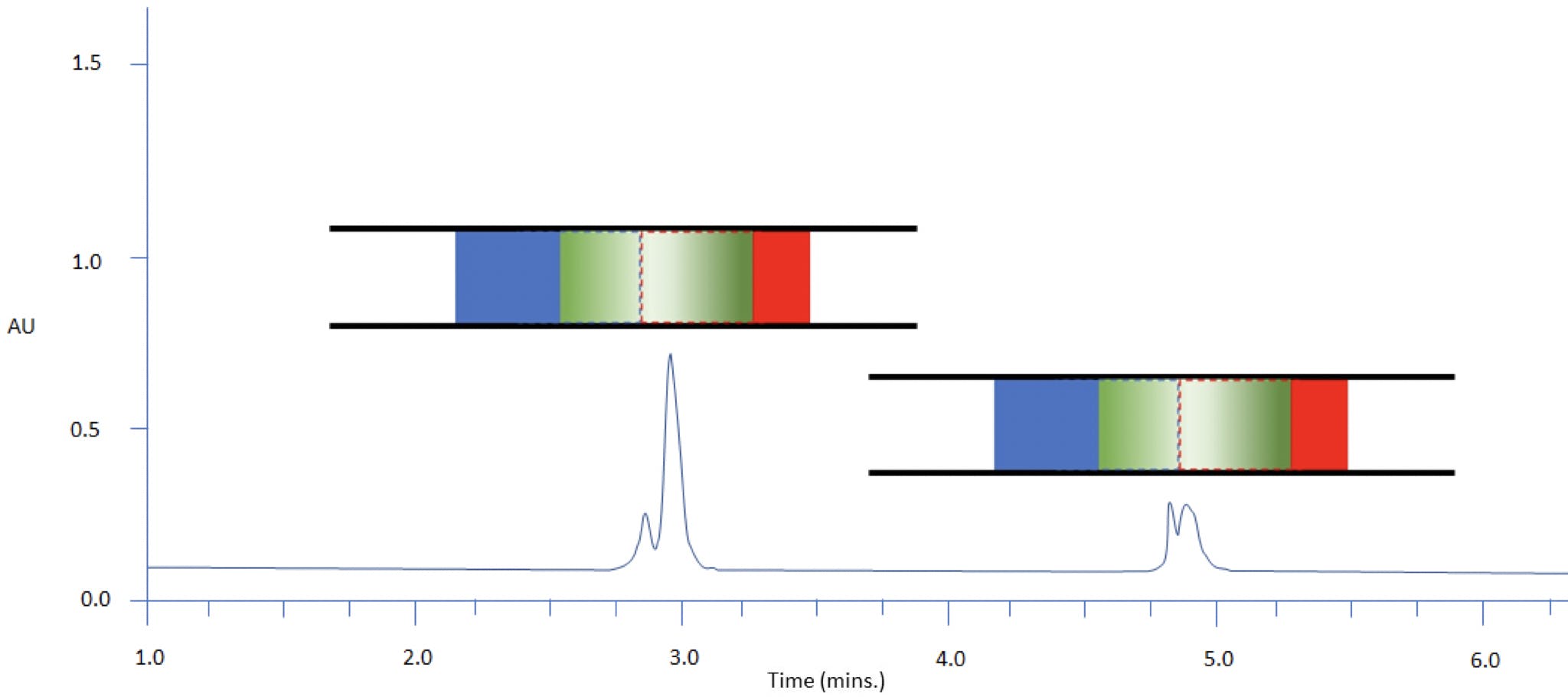

Figure 2: Separation of two model analytes using reversed phase HPLC; C18 100 x 2.1 mm, starting gradient composition 90:10 aq: MeCN for 1 minute followed by linear gradient to 70% MeCN in 12 minutes; Column representations; Green – analyte band / Blue – weaker solvent / Red – stronger solvent; sample diluent 40:60 aq: MeCN; injection volume 10μL.

Figure 2 shows why this might be the case. The red solvent is the more highly eluting sample diluent and the blue is the mobile phase, which has a lower elution strength. As the injected sample mixes at the head of the analytical column the analytes are distributed across a zone which has markedly differently elution strength characteristics and so some analytes travel down the column faster and some will travel slower. The chromatogram in Figure 2 highlights the issues with peak broadening and splitting due to the ‘differential’ sample elution speed of analytes in either the faster or slower eluting solvents. These peak shapes are far from ideal and will certainly give us problems with peak integration and destroy the faith any reviewer of the data has in our abilities as chromatographers!

There are several precautions that we can take to reduce these effects including;

- Using the lowest amount of organic solvent within the diluent that will produce the required solubility characteristics for the analytes of interest

- Using the lowest injection volume possible, to ensure the optimum mixing of eluent and diluent PRIOR to the sample reaching the head of the analytical column (i.e. within the tubing, eluent pre-heating chambers and connections between the autosampler and the analytical column)

- Using a low volume inline filter at the outlet of the injection valve, to promote the mixing of the diluent and eluent, again achieving a more homogeneous solvent plug prior to arrival at the head of the analytical column

However, what if we need to revert to an alternative organic solvent as the sample diluent for solubility reasons or if we wish to avoid a solvent exchange step from our sample preparation eluate? Well, it is possible to use much less conventional, even water immiscible, solvents as diluents if we bear one primary rule in mind, and that is, the solvent we use must elute later than our analytes of interest or if this is not possible, then much earlier than them.

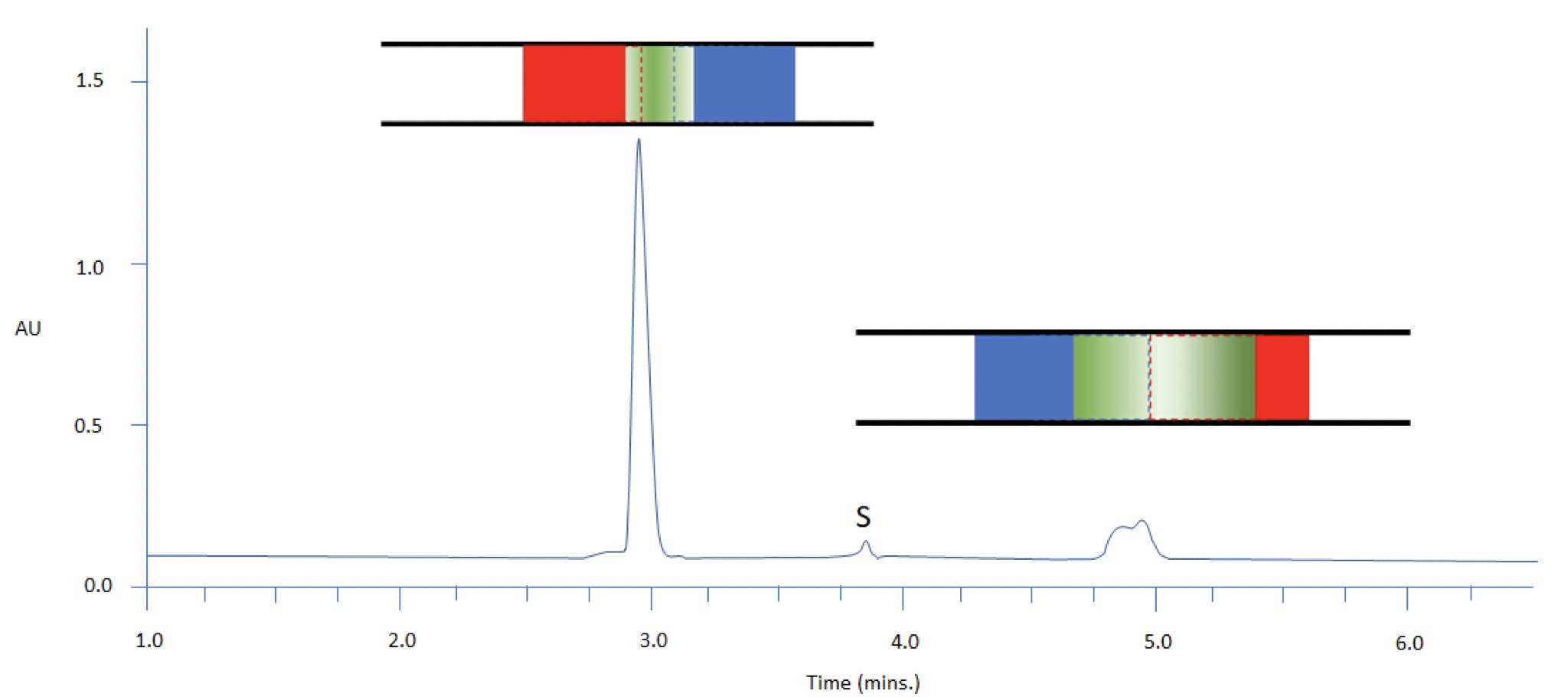

Figure 3: Separation of two model analytes using reversed phase HPLC; C18 100 x 2.1 mm, starting gradient composition 90:10 aq: MeCN for 1 minute followed by linear gradient to 70% MeCN in 12 minutes; Column representations; Green – analyte band / Blue – weaker solvent / Red – stronger solvent; sample diluent Ethyl Acetate; injection volume 10μL; S = sample solvent peak.

Figure 3 demonstrates this principle with our model analytes, unfortunately, we can see that a solvent has been chosen which elutes between the two analytes and whilst the earlier eluting analyte has regained its peak shape, the analyte eluting later than the solvent front gives us a very poor peak shape. Again, we can rationalise this behaviour in terms of the distribution of analyte between the two solvent regions. Where the organic solvent, ethyl acetate in this case, elutes more slowly than the analyte, there is no driving force for the analyte band to broaden as the font of analyte band is not moving faster than the back of the analyte band. Whilst the organic solvent still has a higher elution strength, as long as it does not carry the front of the analyte band with it, then no broadening will occur. Conversely, for the later eluting analyte, we are back to same position as we had in Figure 2, where the front of the analyte band is carried significantly further down the column than the back of the band and peak deformation occurs.

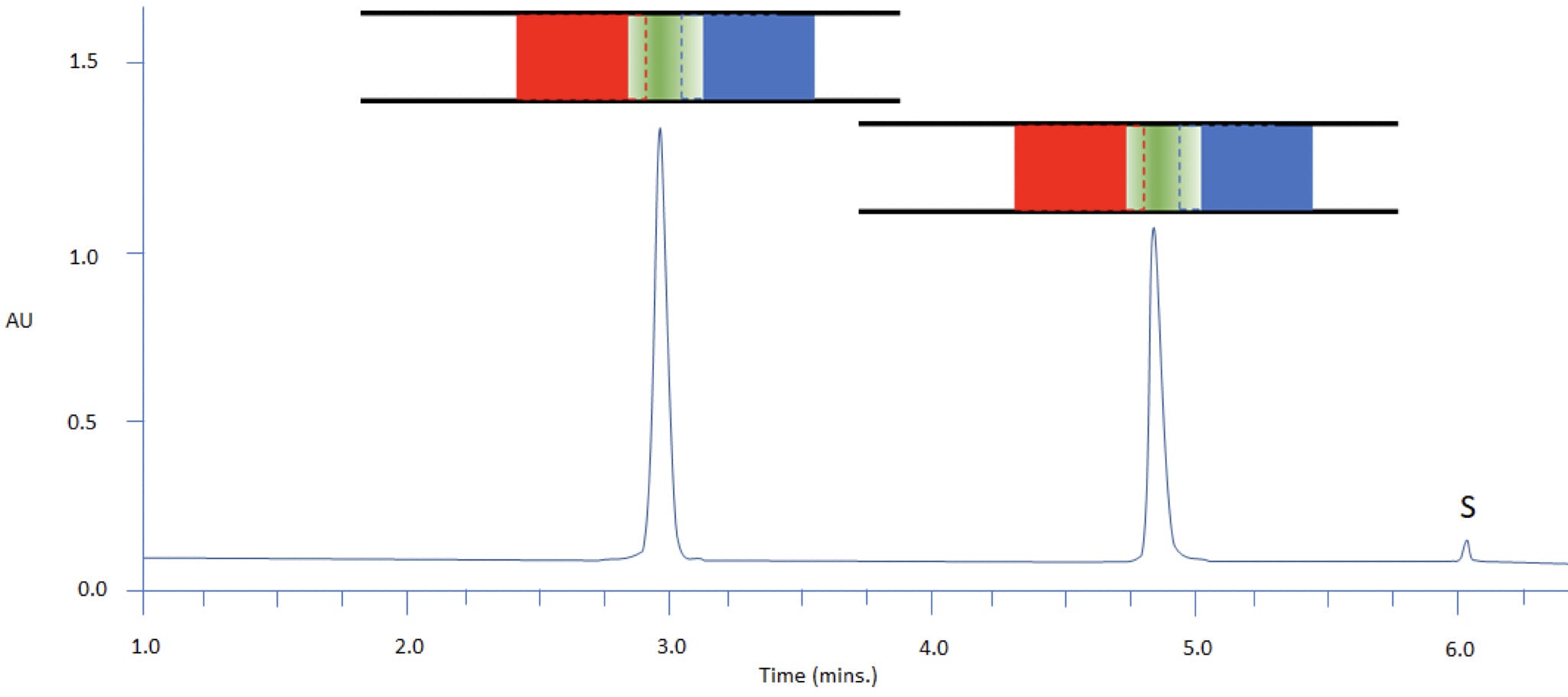

Figure 4: Separation of two model analytes using reversed phase HPLC; C18 100 x 2.1 mm, starting gradient composition 90:10 aq: MeCN for 1 minute followed by linear gradient to 70% MeCN in 12 minutes; Column representations; Green – analyte band / Blue – weaker solvent / Red – stronger solvent; sample diluent MIBK; injection volume 10μL; S = sample solvent peak.

In Figure 4 we have chosen methyl isobutyl ketone (MIBK) as the sample diluent, which elutes later than both of the model analytes. Here we achieve the ideal situation in which both analyte bands encounter weaker mobile phase strength at the front of the band and a more strongly eluting mobile phase at the rear of the analyte band as the sample enters the column. As described earlier, neither analyte experiences a driving force for severe peak broadening or splitting and one could strongly argue that these peak shapes would be acceptable for integration and save our reputation as decent chromatographers!

We should be realistic here and comment that in any situation where our analytes experience differential elution strength environments as they enter the HPLC column, there is a risk of a small degree of band broadening and this risk increases as the volume of the sample injection increases. As such, we should still seek to limit the volume of sample injected to minimise any peak broadening.

Many different organic solvents can be used in this manner, the important point being the relative elution time between the diluent solvent and your analytes, and this may need a little trial and error to optimise. I have had success with iso-propanol, ethyl acetate, MIBK and toluene to name but a few diluent solvents. It is also possible to mix small amounts of acetonitrile with these solvents, in various proportions, depending upon the required solubility characteristics required for your sample mixture.

So, the next time you are considering moving to hydrophilic interaction chromatography (HILIC), using a solvent exchange step for your organic eluate from your sample preparation step or, even more radically, thinking of moving to normal phase chromatography, ask yourself if using an organic solvent as your diluent might just solve your problem with a great deal less fuss!